Surviving With Woodworking In The Real World

/You're probably wondering...

At this point you are probably wondering about progress on the rustic office. Does it seem like it's taking forever? I can tell you that it is, I am literally drying the wood in my shop.

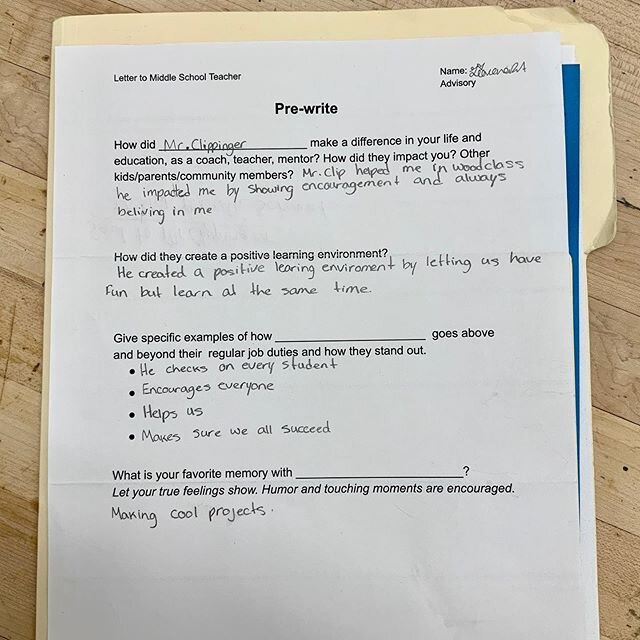

To catch everyone up to speed, I have a rustic office project in my shop. It has been quite a challenge. The clients had the idea of using 10"x10" doug fir beams as the material to build their home office. The beams were left over from the construction of their timber frame home and they are 10 years old.

Romantic Notions

Beams for constructing office.Everybody has heard the stories of using old lumber or timbers that has air dried for years and it is a very romantic notion. Romantic - yes. Challenging - incredibly. There is a false notion that old timbers are dry, stable, and ready-to-use, and they just need to be milled for use.

Beams for constructing office.Everybody has heard the stories of using old lumber or timbers that has air dried for years and it is a very romantic notion. Romantic - yes. Challenging - incredibly. There is a false notion that old timbers are dry, stable, and ready-to-use, and they just need to be milled for use.

These timbers have sat outside unprotected for 10 years absorbing and releasing the environmental moisture. Being that they are 10"x10" instead of 1"- 3" thick, they hold quite a bit of moisture. I had the beams rough milled into quarter sections and I got moisture readings of 15%-18% on the interior with exterior readings at 8%-10%.

This unequal balance of moisture content can cause serious problems with cabinet construction. It is a factor in causing twisted and warped pieces. The way to deter these issues is to take the material down in stages. It has to be continually peeled open, re-sawn close to rough over size dimensions, re-sawn again, then milled to final thickness, and it has to be stickered in between each step to properly air dry and stabilize.

When a client says that they want rustic furniture or cabinets, it really means that they want it to look rustic but that they want doors and drawers to lay flat and operate smoothly. This can present quite a challenge and right now I am neck deep in that alligator.

How Do You Survive?

With the logistical challenges that this situation creates, it can wreck your construction schedule and your income. Progress payments are agreed upon in the contract and made according to benchmarks in the construction. If you can't progress then you don't get paid. That can really cripple your ability to make the house payment.

You have to become good at juggling the schedule. There is always more than one job lined up at a time, but as a small shop, discretion and sound judgement must be used to not get in over your head with too much work at once.

The way that I like to handle it is to have no more than one big job at once with small "filler" jobs that I can plug in here and there as the schedule opens up. It does depend on what opportunities come your way, but after 12 years in the business, I can say that there has always been a good mix of large and small jobs. This is just really the ideal situation to insure cash flow.

The amount of work you have on your plate all at once will vary depending on if you work alone or have any number of employees, but for the most part I am speaking to small shops and individuals. The big job will dominate your time. The small filler jobs may be a quick repair of some type to a full day or two, but the key is that they are flexible and can be held at the ready position until needed.

What I have noticed over the years is that the schedule is very fluid, there are always changes occurring. It is like a river that continually flows the same basic direction but it occasionally changes it's course, sometimes a little and sometimes a lot.

So today's lesson is that flexibility is key to staying busy and to financial survival.

That's all for now!

Remember - You can't live the dream if you don't spend time in the shop.

Your friend in the shop, Todd A. Clippinger

Share the Love~Share the Knowledge

Don't Hold It All In~ Click Here To Leave A Comment!