A Rustic Office

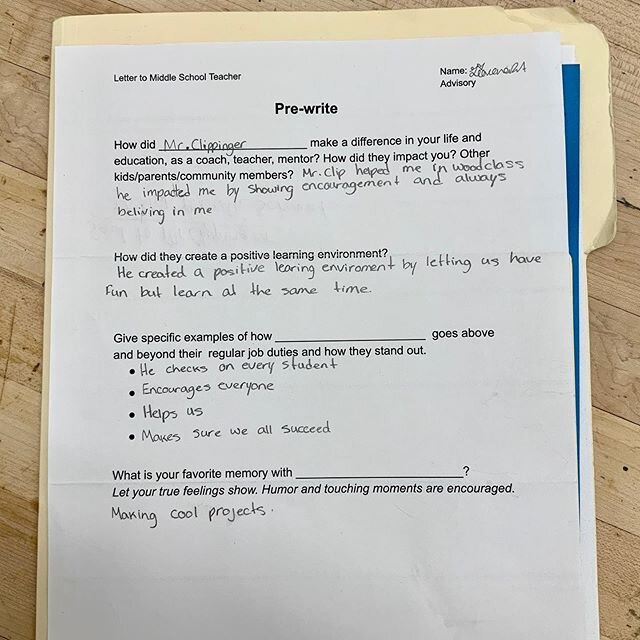

/Difficult Material

The doug fir beams for this project have proven to be the most difficult material that I have ever used. They are 10"x10" beams that have been laying outside for 10 years.

Beams stored outside for 10 years.

The beams have been stacked and stickered but they are completely exposed to the elements. That may include desperately hot temps in the summer to subzero in the winter and all the snow or rain that the seasons bring.

I had the beams rough milled and have continually taken the material down in stages with lots of moisture meter readings to follow it's drying and acclimation process.

Beams rough milled, ready to stack and dry in the shop.

Some of the material has come down to the recommended 6%-8% moisture content but it is still more unstable than kiln dried stock. A good example of this is how the panels require a few days to settle down after being glued up. The moisture introduced during glue up causes them to get a little crazy but they will settle down as the moisture leaves them over the next 2 or 3 days and then they seem to be stabilized.

Panels in glue up.

To get an accurate moisture reading I have extra stock cut due to the anticipated high loss rate. I cut the twisting stock open to take readings on the inside to see how it compares with the outside. This process allows me to get the most accurate reading and sense of stability characteristics.

A Fitting Design

Fortunately the clients want a chunky hand hewn effect. The home is a timber frame with very heavy woodwork in it. The client described it as having a "Fred Flinstone chunkiness to it." That would be an accurate description and it looks good with the wood floors, plaster textured walls, and stone fireplace.

Fred Flinstone chunky interior.

The rough textures of the handwork and saw marks are clearly evident on the wood. To create the effect of milling marks on the desk top I used a belt sander with 50 grit and sanded it in two directions to create an "X" pattern with the scratch marks to create a milled effect. It worked pretty good.

Millwork effects on desk top.

The front edge of the desk was sanded to create a hand hewn effect. I was virtually using the belt sander to sculpt the surface and it worked quite well. The look is proportional to the project and is fitting to the decor.

Rustic front edge on desk.Rustic Desk

The rustic look is a perfect interpretation of this material. It allows me a little grace for the way the wood is behaving. For as challenging as the wood has been, I feel confident that I can get some stable stock for the doors (at least I hope so;)

That's all for now.

Your friend in the shop - Todd A. Clippinger

Share the Love~Share the Knowledge