How I Maintain My Air Compressors

/I work around a lot of other contractors and shops. One thing I have observed is that air compressor maintenance is something that it is often overlooked. This is really surprising, because poor maintenance not only affects the compressor itself, but it also affects the tools that rely on it to operate, and poor air quality can really mess with your finishes if you have a spray system that runs off the compressor.

This video is not intended to be the definitive "All About Air Compressors," rather, I am sharing my habits for maintaining the 3 air compressors that I have. I also think that what I do is very effective and it increases the miles I get from my equipment. Generally speaking, most of my equipment has served me well for a long time.

Let's face it, woodworking tools aren't cheap no matter if you do it as a hobby or as a professional and I need to make them last as long as possible.

At the beginning of the video I put my new shop sticker collection on display in a unique manner. I hope you enjoy that:)

A big shout-out goes to Mike Kapotsy for getting me started on the sticker swap and for the t-shirt which I proudly wear in the video. You can check out his YouTube videos and follow him on Instagram.

Another shout-out to the SoCal Woodshop for sending me one of their logo t-shirts. They are a collective of woodworkers sharing a shop space, pooling their tools, and collaborating on projects for clients. They are a good follow at Instagram.

Here's the Feature Presentation: How I Maintain My Air Compressors.

I hope you enjoy it as well as find it interesting and helpful.

Your friend in the shop,

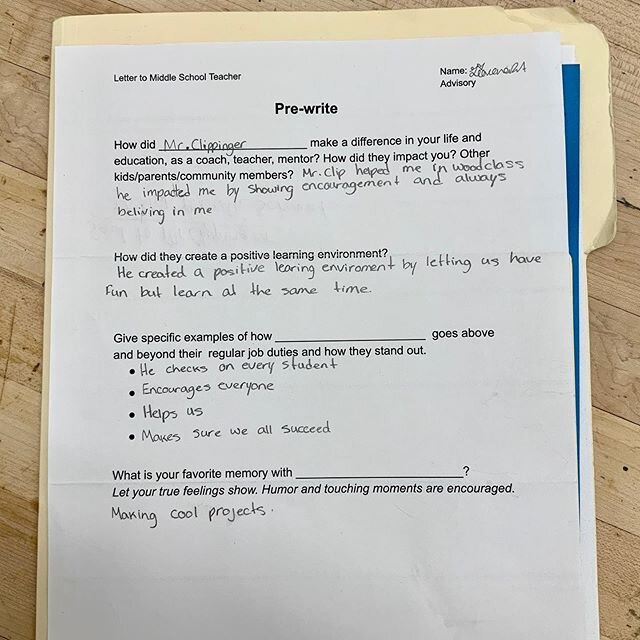

Todd A. Clippinger

Share the Love - Share the Knowledge