Work Published in Magic City Magazine

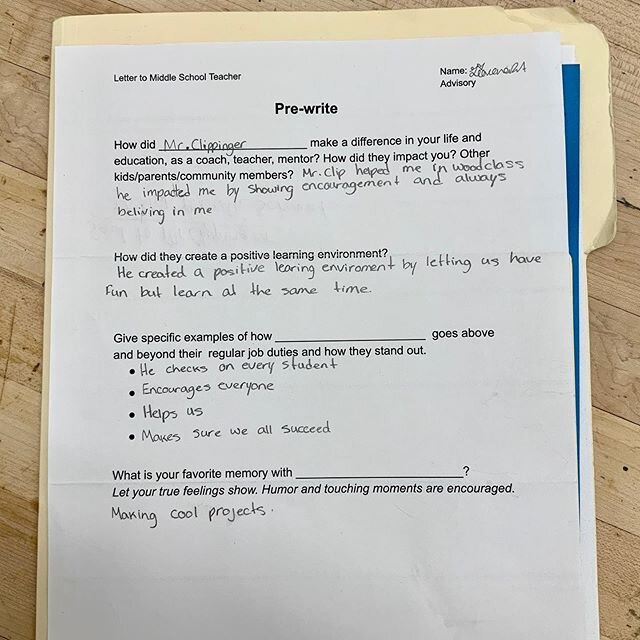

/One of the remodeling projects that I had been working on for the last few years got some nice coverage in the Magic City Magazine.

Magic City Magazine is a pretty slick publication that covers stories of design, fashion, food, and the happenings around the Billings, Montana area. (Billings is known as the Magic City, hence the magazine name.)

The story covers 2 remodel projects of smaller homes that had some creative and higher quality remodel work done to them. Usually, any of the stories covering homes and design always feature the biggest, most expensive homes, so it was nice to see that smaller homes can also showcase high-end work.

As you read the article, I know it is difficult to know what I really did in the remodel, but to summarize: I built the arch in the front of the house, built & installed cabinets, did custom built-ins, rebuilt the stairs going to the basement, framing, removed walls, built walls, sheetrock, mud work, built under-stairs storage, built a custom door for that storage, installed doors, trim work, and blew my back out moving sections of bowling alley for the yoga studio floor (that was brutal.)

The clients and I were both a bit disappointed that the bathroom did not get any coverage, it was pretty sweet. I vaulted the ceiling to follow the roof, installed a skylight, and built a cool modern cabinet for storage out of black walnut.

It was great getting a mention and having my work covered in the article. A big thanks goes to my clients who gave me the opportunity to work on their house and become friends along the way. They had a great sense of creativity and were great to work with.

Check out pages 25 through 29 of the digital edition of Magic City Magazine.

You can follow my latest projects on my Instagram feed and, stay tuned, I am working my way back to producing more video;)

Your friend in the shop-

Todd A. Clippinger