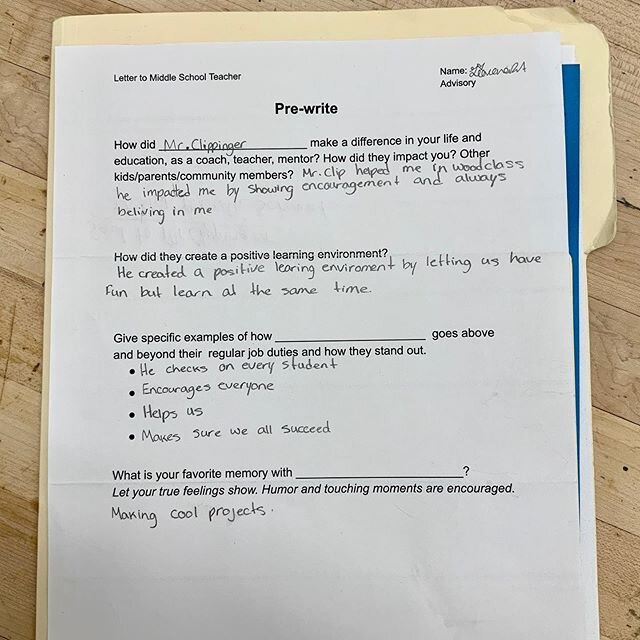

Backstory on the Fireplace Prototype Seen in WOOD Magazine

/Here is the story on the fireplace prototype that is published in the current issue of WOOD Magazine (May 2014, Issue 225.)

My clients have a gas insert installed into an old fireplace. The insert did not fit completely into the fireplace and the surround was just outright hideous. This is when I got the call to see what I could do for them.

The original fireplace with an ill-fitting gas insert, poor design, and just outright hideous.

We had an initial meeting and talked over some ideas. They wanted to move forward with the project even though I had not hammered out anything solid. They really liked my ideas and trusted me since I had done work for them before.

At that time, I was hitting a point of serious burnout. When I hit a period of burnout, I have issues with trying to make the thought process flow as it normally does. I don't do well sitting in front of the computer drawing in SketchUp and I can't make a go of it on paper. But I still do well handling something tangible such as model parts. Since my mind was fried, I was not even going to deal with doing conversions for a scale model so I just built the model in full scale.

Determining proportions on fireplace prototype.

Yeah, I know you're thinking, "Why doesn't he just take time off?" Well, I have my own business and it doesn't work that way. I gotta make hay when the sun shines because January thru April are typically very lean months. When the jobs start coming in again I just work until I drop.

For modeling in cardboard, I purchase 4'x8' sheets from Xpedex. They have shipping supplies such as boxes, slip sheets, packaging, etc. Another good place to get cardboard sheets is from Costco or Sam's Club. If you ask they will usually let you take the slip sheets that come between merchandise on pallets. Slip sheets are typically 42"x48" (approx.) For assembly, I just use a hot glue gun to put it all together, this is great as it works out fast and holds just fine.

Building the fireplace prototype in full scale, complete with varied thicknesses and reliefs.

After presenting the prototype to my clients, they were just absolutely impressed and sold on the project. Although it impressed them that I built a full scale model, the fact is I did it because I could not hardly keep a clear thought in my head due to burnout, but I still pulled off a great design.

Here is one key to coming up with a good design: use the architecture of the house and the overall design of the environment to guide you on the project. You might do a flawless job on a project, but if it does not flow well with the overall design of the house, that is a point of failure.

One point to keep in mind when using a model: The model helps give a good sense of how the project will look and is a point of reference for what works and does not work. Changes do not require a new model be made, the changes agreed upon are implemented in the final project itself.

The fireplace surround installed and complete.

If you are interested in seeing the progress photos of the project that I posted for my clients to follow, you can check them out here: Fireplace Project Album

In the fireplace album you will see the original reference photos, lots of progress photos (especially of the cardboard model), and the final project from a few different angles. There are no captions, the images alone pretty much tell the story.

That is all for now and until next time, be safe in your own shop!

Your friend in the shop-

Todd A. Clippinger