A Lesson Review

/Pop Quiz!

Didn't you just hate the pop quizes back in school? Well I have one for you today.

What did we learn about monitoring wood moisture content?

• Take readings often.

• Take readings from various locations.That includes the middle and ends of the stock (edge or face) and if you have an opportunity, from the inside when it is cut open.

• Observe the relationship of the changing moisture content and the behavior of the wood movement. Also compare these things to the specific grain patterns and the location of movement in a board. For example: where a twist may center itself.

These things are important to observe as you learn to understand a board and what it is telling you.

Yesterday I was working a piece of the doug fir beam. It is a beautiful piece that I am making a desk leg out of.

5"x5" Beam

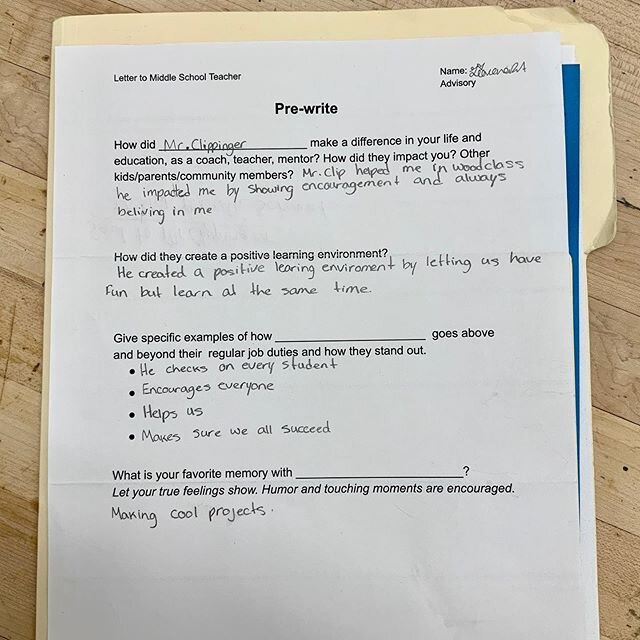

After I cut the stock into sections, I took meter readings from various locations on the ends of the freshly cut wood.

Normally, if a board is sitting for a long time, I do not take readings from the end. But, if I just cut it open, I will meter the fresh cut end that came exposes the interior of the board.

Here is something that you should take note of. My stock is 4 3/4" square, if I meter the center of the stock, the moisture content will register higher than if I meter closure to the outside edge.

See the difference in the readings of the following pictures. Moisture Reading 8.5 Moisture Reading 5.3

This is not alarming and is normal. The wood obviously dries from the outside face in and from the ends in. What this also means is that when it is milled open, it should have a chance to equalize before putting it into a project to avoid issues of twisting.

The part of the wood that contains a higher moisture content is going to be swelled in comparison to the drier part of the board. It will be necessary to let it settle down.

Pitch - A Sticky Issue

This doug fir stock came from beams that sat outside for about 10 years. Most of the pitch has solidified and no longer runs.

This is a good thing because you should see the amount of pitch that some of this wood has. If this was fresh pitch, it would be running all over the place.

Pitch PocketsMore Pitch Pockets

Even now the pitch has been creating a mess of my tools. After milling out a tenon on the tablesaw...

Tenon cut on tablesaw.

just look at the pitch build up on the throat plate!

Pitch on tablesaw.

The pitch has just enough body to it that it can be easily scraped off and the residue dissolved with solvent.

Pitch scrapes off easily.

Fortunately for me, the design of the project is rustic and the clients are familiar with the nature of the wood.

This allows me some grace so any issues with finish will be minimal. I will need to seal the pitch with shellac to deter problems, but I am not sure that I can outright avoid them.

That is all for now. Be sure to check back regular and see what's new!

Your friend in the shop - Todd A. Clippinger

Share the Love ~ Share the Knowledge