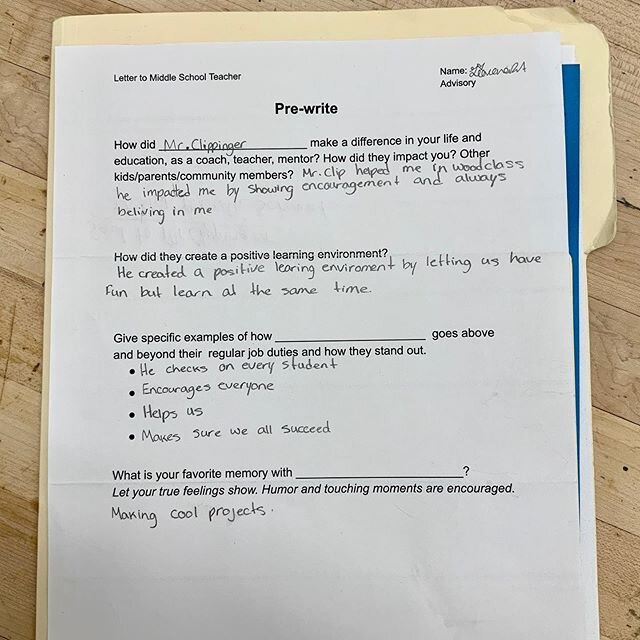

Congrats To Tommy MacDonald

/With Norm's New Yankee Workshop no longer in production, it felt as if there was a void on PBS and everyone has been wondering who would step up to the airwaves or if anybody would.

Well, the word is out - Tommy MacDonald has publicly announced his contract to produce a new woodworking TV series with PBS.

Tommy brings a great passion combined with his skill and knowledge for teaching woodworking to the viewing audience. This is already evident in the series of videos that he has produced himself and they can be seen at his Major League Woodworking site. You will find them under the button labeled the "207 Show."

Tommy also has a vibrant online community where one of the big topics they discuss is design. They cover everything on the topic of design from the history to specific elements that define a style and the people that influenced the design world. If you are interested in checking in on the community, stop by the 207 Forum.

Tommy has a guest moderator staffing the design forum and it is none other than Neil Lamens. Neil brings an incredible amount of knowledge in the history of design and furniture manufacturing to the woodworking community. His talent and knowledge is a great compliment to that of Tommy's.

Neil is no stranger to woodworking videos as he has produced several himself. You can check out Furnitology Productions to see Neil's videos and gallery.

When you stop by Tommy's site you will immediately notice all the work that has gone into the design and attention to detail. Tommy is sure to bring the same level of perfection to his show in sharing with the woodworking community.

Another mention has to be for Dave Pruett. He is a good friend to the woodworking community for all the videos that he has produced to share woodworking skills and doing personal interviews. Dave can be followed at his blog "The Folding Rule." Dave was lucky enough to get video of Tommy's announcement for the new PBS show.

Tommy - we wish you great success with the new show and will be looking for you on the air!

That is all I have for now so I will leave you with the video of Tommy's announcement.

Your friend in the shop - Todd A. Clippinger.

Share the Love~Share the Knowledge